Buying a Single-Phase Vs. Three-Phase Generator

Single-phase and 3-phase generators may be cousins in the power-producing family tree. However, businesses and building managers should avoid confusing the two for their facility’s energy needs. While both generator types can power equipment as an alternative to traditional power sources, there are significant differences between the two, including what they can power and for how long.

When choosing a reliable generator for your operation or facility, understanding the difference between a single-phase and 3-phase generator is essential. With the right knowledge, you can select an effective generator set for your needs to avoid common pain points like weak power or costly energy bills. Consider the information in this guide to determine which generator type is best for your operation.

- Both use Alternating Current (AC): Alternating electric currents reverse direction rather than continuously flowing in one direction. As such, AC electricity produces higher levels of variable power.

- Both contain power cycles: Power cycles have peak and lowered outputs based on how electrons move in the current. While both single-phase and 3-phase generators use power cycles, they also differ in this area. As you’ll see below, their names suggest how many cycles each type uses.

The Difference Between Single-Phase and 3-Phase Generators

While single-phase and 3-phase generators are built on the same AC flow concept, one fundamental difference sets them apart and ultimately gives each its name. Each uses a different number of conductor wires to provide power output. The conductor wires allow each generator to produce different power outputs. As such, their power cycles run differently depending on how many conductor wires the generator has.

Single-phase generators produce one AC flow that fluctuates from 170 degrees to -170 degrees. The continuous oscillating wave reaches its peak output, which is when the most power is generated, and returns to a low output. Producing large amounts of power is more difficult with a single current because the wave is constantly dipping back down. However, the opposite is true of 3-phase generators.

The same concept applies to 3-phase generators, though they produce power through three different conductive wires and a neutral grounding wire. These wires, or phases, are all offset by 120 degrees and are synchronized so they never touch or cross paths. Offsetting the phases ensures one of the three waves is reaching its peak at any given moment. This arrangement provides a more even and continuous power output because one of the conductors is always at its peak. This aspect is what makes 3-phase generators so powerful compared to single-phase units.

You can think of 3-phase generators as three single-phase generators in one generator set. When looking at both types of generators, each of the same size, the 3-phase generator has 180% more capacity than the single-phase model. That additional capacity greatly affects the unit’s power, enabling 3-phase generators to produce far more power over a longer period. That difference is significant, especially when you need all the power you can get.

Compared to single-phase generators, 3-phase units offer significantly more power. The three conductors in the generator’s continuous cycle make it stronger and more suitable for heavy-duty applications like powering large commercial and industrial machinery. Meanwhile, single-phase generators are only ideal for smaller applications like powering household electrical circuits.

How a Single-Phase Generator Provides Power

As its name suggests, a single-phase generator uses a single AC wave to create kilowatt outputs. Since these generators only work from one “line” of power produced between fewer conductive wires with up-and-down output cycles, single-phase generators will not provide as steady a power source as their 3-phase counterpart. As the single “power line” climbs to its peak and falls back down, so does the power level it produces.

Luckily, single-phase generators don’t wholly “drop out” or completely lose power, even at the lowest point. Low cycle currents typically remain unnoticeable unless this generator type runs over capacity. For example, commercial lights are a staple application for single-phase generators, yet they cycle so fast that flickering caused by current low points is imperceptible to the human eye.

In total, a single-phase generator is one made up of the following characteristics:

- Relatively light loads

- As few as two winding components

- Less conductive winding in general

- A single voltage-produced current

- More prone to voltage disruption

- Higher maintenance costs and lower initial purchase costs

- Less efficient and less powerful

How a 3-Phase Generator Provides Power

A 3-phase generator has three currents that run in sequences simultaneously. These generators can produce robust and continuous power because the sequenced currents always have one current near peak power. These currents require a strong voltage to provide constant power.

A 3-phase generator patterns its three conductor wires and one neutral wire to cycle at 120-degree offsets to maintain power for more intense applications or mission-critical machinery. The 120-degree proration means that as one current’s cycle is at its lowest, another will be at its highest, offering complementary wavelengths that work in tangent to deliver stable amounts of power.

3-phase generators offer an even balance between the power provided and the cost to build and maintain. They’re also more versatile, with more than one way to power equipment. For example, operators can opt to sync all three current cycles to power one large piece of industrial-grade equipment. Or, each conductor wire can connect three smaller pieces of equipment to individual current lines held within the same 3-phase generator.

The former is often the case in factories and industrial applications to power a single machine or system, while the latter works in applications like multi-story office buildings to power elevators and the office’s suite of desktops.

In total, a 3-phase generator will be comprised of the following features:

- Three currents fluctuating at 120-degree intervals

- Three copper winding components

- More intricate winding or wiring

- Lighter and more efficient

- Power heavy and industrial loads or distribute the load to numerous applications

- More economical, reliable and robust

The three conductors give these generators a higher power factor. These generators can power large, complex systems because they produce higher voltage output. Stronger voltage is necessary to power systems in certain applications and facilities effectively. In these situations, three conducting wires are highly valuable and often needed to produce adequate power for operation.

The Advantages of a 3-Phase Generator

Understanding the functional and mechanical benefits of a 3-phase generator plays a significant role in picking one that works best for you.

However, while single-phase and 3-phase power are often pitted against each other, it bears noting that the defining element in your purchasing decision is what you will use this generator for. It’s an intuitive question, and it will help you see the actual benefits of the generator for yourself rather than relying solely on confusing spec sheets or flashy salespeople.

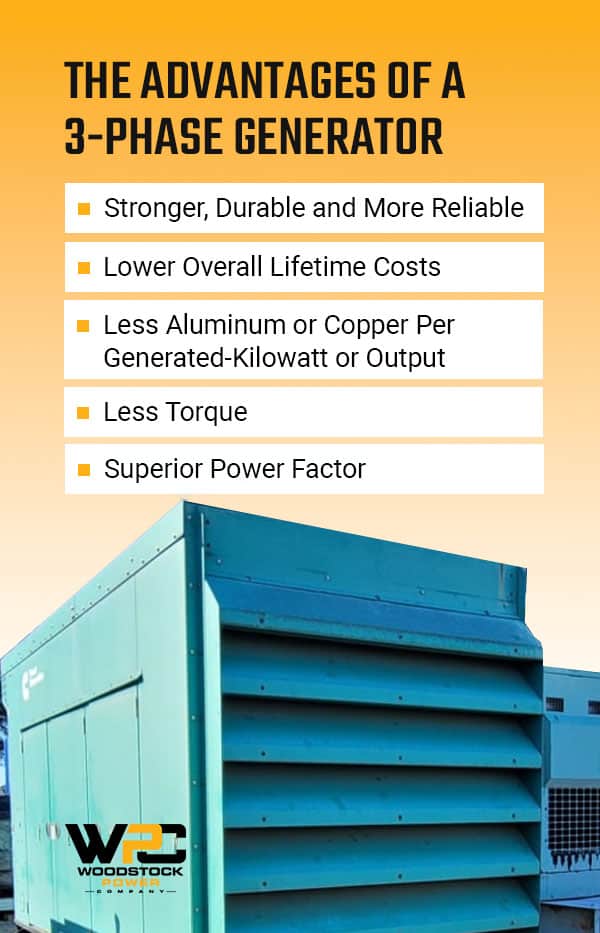

For industrial, commercial and agricultural applications, 3-phase generators are your surest bet. The advantages of 3-phase generators to these industries are extensive, including:

1. Stronger, Durable and More Reliable

It bears repeating that the most significant advantage of 3-phase generators is their high levels of power output and even higher levels of efficiency. They are the workhorses of industrial equipment, heavy machinery, large office buildings and facilities alike, delivering steady streams of electricity that are staples in high-demand operations.

2. Lower Overall Lifetime Costs

While they may be more expensive to acquire upfront, 3-phase generators are the calculated winners when it comes to maintenance, system updates and general upkeep. They are more stable and resilient due to less wear-and-tear from torque, heavy loads, pulsating distribution and more. What’s more, when you factor in cases of system downtime or production halts due to single-phase degeneration and patches, 3-phase generators become even more cost-competitive.

Additionally, running several single-phase generators can be costly when trying to power large applications. For the same voltage and power, the transmission cost for a 3-phase generator is less than a single-phase one.

3. Less Aluminum or Copper Per Generated-Kilowatt or Output

This initially sounds confusing, since there are more wires involved in a three-cycle generator compared to a single cycle’s traditional one or two. However, 3-phase generators actually have what’s called a lower power transmission, meaning they need less conductive materials to produce the same amount of power at the same level of volts.

In this case, that means 3-phase generators have lighter copper or aluminum wiring components than single-phase generators, making the whole unit potentially lighter but still more efficient.

4. Less Torque

Less torque in your generator means fewer mechanical vibrations. This, in turn, helps complement the superior reliability of the 3-phase generator over its one-phase counterpart.

Extensive levels of torque will cause a domino-like spiral of effects on your unit. Your AC waves become disrupted and less stable, as magnets shift out of place or other weights and forces damage mechanics, which then means irregular cycles. With harmonious cycles as the backbone to AC generator types, you’ll end up with a less sturdy and less functional 3-phased unit.

5. Superior Power Factor

Most 3-phase generators average a .8 power-factor rating. That’s nearly 1.5 times higher than the typical power factor of a single-phase generator of the same size and weight. These higher power-factor numbers mean larger final outputs capable of handling your industrial applications.

When Should You Choose A Single-Phase vs. 3-Phase Generator?

The most significant factor in choosing a single-phase or a 3-phase generator is what you intend to use it for. Consider what kinds of equipment or devices need to be powered, how often and for how long.

When You Should Choose a Single-Phase Generator

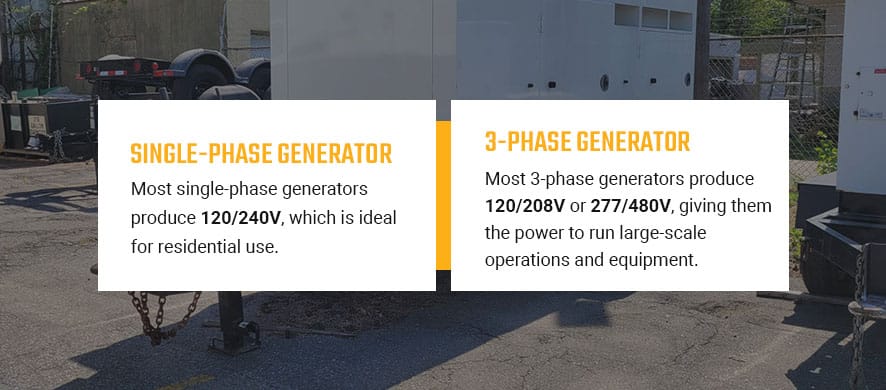

Most single-phase generators produce 120/240V, which is ideal for residential use. They’re typically not used for commercial or industrial use because they lack the capacity necessary for high-volume equipment. Because single-phase units are best for residential uses, they are only recommended for low-power appliances and equipment, such as:

- Individual or small sets of desktop or laptop computers

- Individual lighting systems

- Televisions

- Modems

- Backup portable generators

Business owners and facility managers should only consider single-phase generators when applications require power less than 240 kilowatts. Generally, single-phase generators are not meant for scale. They are also not ideal for powering advanced or around-the-clock equipment unless that equipment comes highly specialized or is somehow buffered by another power source.

You typically shouldn’t use single-phase generators for most of your facility’s major systems like heating, cooling, air ventilation, elevators, large electronic systems, and industrial or production equipment. These systems likely won’t function without a proper high-output source, like what’s provided with 3-phase power.

When You Should Choose a 3-Phase Generator

Typically, 3-phase generators are the best choice for commercial and industrial usage. Most 3-phase generators produce 120/208V or 277/480V, giving them the power to run large-scale operations and equipment. Some can be configured into a 120/240V 3-phase generator, though most applications for a 3-phase will require more voltage. They can withstand longer run times, sustain higher voltages, and perform with maximum stability and reliability.

Business owners and facility managers should consider outfitting their buildings with 3-phase generators in preparation for a power outage or emergency. In some industries, a power outage can cost thousands in profit-cutting expenses per minute — not to mention, in some cases, put lives at risk. Your facility risks losing revenue and other business-critical liabilities without a backup power source.

You should choose a 3-phase generator if your plant or operation relies upon any of the following:

- Industrial equipment: This includes computerized and manual heavy-load engines and large motors, conveyor systems, commercial refrigerators and industrial fabrication machinery.

- HVAC systems: HVAC systems include industrial or commercial-grade electric furnaces, boilers, baseboard heaters, central air conditioning, space heaters and air ventilation systems.

- Agricultural equipment: These include heavy-duty equipment like open standby units, tractor-driven power take-off units or engine-driven alternators.

Industries and Situations Requiring a 3-Phase Generator

3-phase generators are essential for many business types and situations. The following industries need proper 3-phase generators to backup operations, augment specific equipment or produce power in the field to reach peak productivity.

1. Small Batch and Continuous Manufacturing

Numerous studies have found manufacturers have the most to lose from a power outage or disruption. Whether small-batch production lines or an around-the-clock fabrication facility, a reliable, industrial-grade power source is vital for maintaining a production line. Facility managers work to ensure their power grids are secured, sustained and buffered with their own backup 3-phase generators to keep machines operational and computer systems regulated.

If a power outage occurs or the facility doesn’t receive enough power from the utility company to power the operation, 3-phase generators can take over. These generators allow manufacturers to maintain consistent production and avoid costly downtime.

2. Food and Beverage Processors

Perishable food and beverages rely upon continuous power to keep cold-refrigeration and other preservation storage methods working. With inventory extremely liable to contamination and shortened or tainted lifespans, a single power outage can force you to throw out thousands of products and the associated revenue. Having 3-phase backup generators on-site can prevent such situations. At the very least, food and beverage processing operations should have 3-phase generators to ensure temperatures are regulated and air ventilation cycles are always sterile.

3. Multi-Story Office Buildings, Towers and Skyscrapers

The large and complex electrical systems outfitted in multi-story buildings require an equally dynamic system — 3-phase generators are the natural choice for electrical engineers and building managers to regulate power on each floor. Moreover, these power levels must be consistent regardless of the story or its electricity demands. Only 3-phase generators carry the versatility to distribute currents to multiple applications, as well as with the steadiness and uniformity high-rises need.

These generators can provide equal power distribution across all building levels to keep businesses, apartments and the entire building up and running.

4. Agricultural Equipment, Attachments and Power Tools

Few sources of power can meet the requirements of agricultural work. Electricity is necessary for numerous farming tasks and equipment, from temperature and ventilation regulation in livestock buildings to powering irrigation systems or planting and harvesting machinery. With these daily operations, static and portable 3-phase generator units are the go-to powering choice to complement current systems or boost the functionality of field equipment attachments and tools.

For example, portable 3-phase generators could be used in the field to provide electricity for power tools. This is especially useful for vast agricultural properties when work needs to be done where the main electricity doesn’t reach.

5. Data Centers

As cloud-based and outsourced data storage continue to rise, so does the importance of powering those centers. These massive facilities cannot risk a power outage — even for as little as a few minutes — as outages spell the potential for irreversible records loss or damage on top of subsequent liability complications. Those in the finance, telecommunications, health care or IT sectors need reliable data centers fueled by 3-phase power sources to keep data transactions smooth, secure and glitch-free.

6. Health Cheare

Hospitals, emergency rooms, doctors’ offices and other health care facilities require significant power to run essential, life-saving equipment. Backup generators for the health care industry must be powerful and reliable, so 3-phase units are preferred. These generators produce the necessary power to run equipment like ventilators, lighting, surgical tools, electronic medical record systems and computers.

New or Used 3-Phase Generators to Power Your Commercial or Industrial Operations

You have questions, and we have answers. Choosing the right phase generator for your property is not something you decide on a whim. Woodstock Power can help you consider your exact grid and power layout and operational needs to find the right generators to tie it all together.

We’re always here to answer your inquiries and protect your business from expensive downtime. Reach out today through our online contact form or call us at 610-658-3242. We can’t wait to work with you.

Follow us on LinkedIn, YouTube, Facebook, and Twitter for more info about commercial generators!