Parts of a Generator and How They Work

A generator is a backup power source used during power outages caused by emergencies, inclement weather, routine maintenance and other factors affecting primary energy sources. Similar to residential generators and their ability to power homes during a blackout, commercial generators have the same functionality on a larger scale.

Generators are extremely important to industrial and commercial facilities, as these buildings heavily rely on equipment requiring high power ratings. Because of the high power demands of commercial enterprises, commercial generators are larger and have sturdier components, bigger engines and higher energy outputs.

Before installing a new generator, knowing how it works and what each of its parts does is essential to ensure its efficiency and the safety of those working around it.

How Does a Generator Work?

Each generator component plays a key role in how the generator makes power. Understanding a generator’s basic mechanics will you help solidify its ease of operation and functionality.

One of the most important things to understand about any generator is that they do not create energy. Instead, they convert energy into usable power using either direct or alternating currents.

Generators with direct currents (DCs) require a storage battery or electromagnetic induction with a unidirectional flow to produce currents. Alternating currents (ACs) flow from zero to a positive maximum, back to zero and then down to a negative maximum and back to zero.

The most commonly used commercial generators are diesel and natural gas. Generally, diesel generators have a tank attached or connected to a larger tank that users fill with fuel, which acts as their primary source of fuel. The engine then uses this fuel, converting it to mechanical energy by forcing it into a circuit to create an electrical current.

For example, a diesel generator starts up and generates power automatically during a power cut. It does this by converting energy from burning fuel, using the heat produced from its air compression.

Natural gas generators are usually attached to a natural gas pipeline is the utility is available in the installation location to maintain a steady supply of fuel. In some cases, it may be possible to convert a natural gas generator to run off propane (LPG) and then connected to larger propane tanks on-site to run in standby.

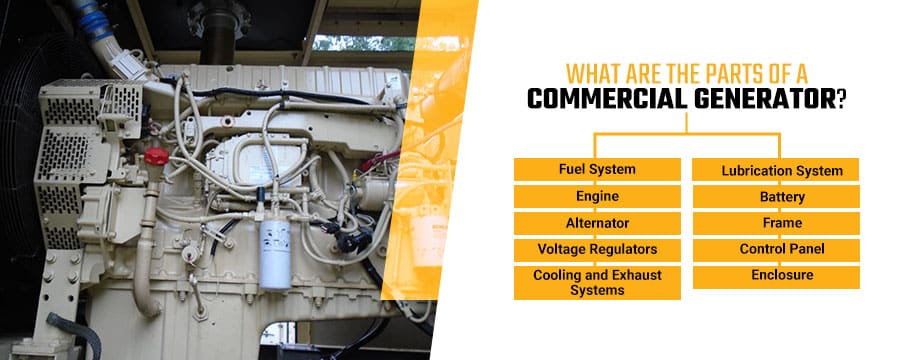

What Are the Parts of a Commercial Generator?

As an essential item for emergency situations and power outages, generators have many parts that contribute to their functioning. Each part of a generator has a unique purpose that allows the machine to operate properly and supply energy where you need it.

Because businesses and companies rely so heavily on electricity to keep their employees safe and products functional or usable, it is important to understand how your generator works and what each part does. Here are the key components of a generator you should know to understand where backup power comes from and how these machines supply it to your job site:

1. Fuel System

One vital part of a commercial generator is the fuel system. Before a generator can output mechanical energy, you must supply it with a fuel source so that it can convert that source — either natural gas or diesel fuel — into chemical energy that converts into mechanical energy and eventually electric outputs.

When evaluating the fuel system of an industrial generator, let’s begin with the fuel tank in diesel generators. Diesel generator fuel tanks can either be an auxiliary or a tank mounted to the generator known as a diesel base tank. The amount of fuel the tank can hold dictates its power generation capabilities in terms of duration. To put it simply, the larger the diesel fuel tank, the longer it can run to power the generator and provide backup power in the event of a power outage. Often times, these diesel fuel tank capacities are calculated against the size and kW rating of a diesel generator, including estimated fuel usage and load. The diesel base tanks are often complementary to the diesel generator and will approximate how much time the generator will run off based off capacity. For example, a 300 kW diesel generator with a 555 gallon diesel base tank will be considered a 24 hour diesel base tank.

Connected to the tank are pipes or fuel lines that lead to the generator’s engine. These fuel transfer pipes can be above or below ground and transport fuel from storage to the engine. The fuel system also includes pumps that use pressure from electric motors to draw fuel from the external tank and inject it into the engine cylinder.

When it comes to natural gas generators, these types of generators are generally required to be hooked up to the main gas utility. This enables a natural gas generator to have a steady fuel supply, barring any utility work, upgrades, or the gas utility being shut off due to natural or man made disasters. This means that there is no need to worry about fuel storage capacity, as long as the main utility continues to be up and running.

An important note about fuel injection systems is that natural gas and diesel fuel generators use different injection systems and are not interchangeable. These different fuel sources require injection timing and other similar parameters specific to fuel type.

Any excess fuel not injected into the cylinder returns to the tank. Ultimately, returning fuel to the tank can reduce the engine’s horsepower because the returned fuel has a higher temperature than the stored fuel. This is because it absorbs heat from the injectors. If the temperature becomes too high, this shuts the system down. Because of this consideration, many generators include fuel coolers that help regulate the fuel temperature.

Another important note about generator fuel systems is that they have control equipment so that you can monitor the pumps, storage tanks, fuel inventory and leak detection.

2. Engine

The engine is another key operator within the parts of a commercial generator. Like natural gas or diesel engines in automobiles, generator engines are where chemical energy, or your fuel source, converts into mechanical energy.

Different generators have different engine sizes, which is important to keep in mind when choosing or servicing your machine’s engine. Engine size correlates directly to the generator’s maximum power output due to horsepower (HP). This aspect means larger engines can generate greater amounts of energy output, while smaller engines have a smaller energy output.

Related to the maximum output of energy produced is horsepower, the unit that measures engine power. The maximum produced electricity output corresponds with horsepower, meaning larger engines with greater electricity outputs have a greater horsepower than smaller models.

Horsepower also explains in greater detail the importance of fuel tank temperature regulation. Because return fuel is warmer than stored fuel, the stored fuel then increases in temperature. For every 10 degrees Fahrenheit that the stored fuel temperature rises above 100 degrees, the engine’s horsepower drops by 1%. Larger tanks are less affected by the temperature of return fuel, ultimately allowing larger engines to continue operating at a higher horsepower.

The size of your company’s generator engine will correspond with how much electricity the generator needs to produce. Larger companies and industries that rely more heavily on electricity will require generators with larger engines.

It’s important to also note that diesel generators and natural gas generators differ in that natural gas generator engines have spark plugs and are spark ignited, which is an item to consider when searching for a backup generator. This is due to the fact that natural gas generators will be require more regular inspection and maintenance to ensure that it can continue to operate at peak efficiency, as well as ensure all safety measures are being taken when operating a natural gas generator.

3. Alternator

Also called the generator end, the alternator turns mechanical energy into electricity. This process begins as the engine burns fuel and transmits it to the alternator. The alternator houses two major components that allow the generator to effectively and efficiently produce energy: the stator and rotor.

The stator is a stationary component that contains a set of electrical conductors that are coils wound together housing an iron core.

The rotor (Armature) is a moving component that produces a magnetic force that cause electrons to move and produces electricity.

The stator is the alternator’s stationary facet. It contains electrical conducting coils wound together around an iron core. The rotor or armature is the moving component that produces a magnetic force. The magnetic force causes electrons to move, which creates energy.

More specifically, the rotor utilizes mechanical energy from the engine to move around the stator and create a magnetic field. This process produces a different voltage or electrical potential between the stator’s coils, creating the generator’s alternating current output.

4. Voltage Regulators

Automatic voltage regulators (AVRs) are automatic devices in generators that help keep voltage levels constant. As an essential component of generators, they work to stabilize the output voltage by preventing fluctuating voltage levels and sustaining the alternating current within the right voltage level range.

These regulators are an important part of the generator because they help the machine meet your commercial power needs and your equipment’s power requirements. If the generator does not maintain its allowed voltage at a constant rate, this negatively impacts both generator performance and the function of any equipment powered by the generator.

All appliances and machinery have different ranges of voltage preferences where they work at their peak performance. Any voltage level above or below this range can cause performance difficulties or appliance failure. Unregulated generators, or generators without an automated voltage regulation system, are insufficient. When the voltage produced constantly changes, this reduces the longevity of your appliance and of the generator itself.

With long-term inappropriate voltage use, your equipment can suffer from permanently reduced efficiency and even become damaged. The generator voltage regulator helps eliminate equipment damage or safety issues caused by voltage fluctuations, as AVRs work to provide surge protection against electrical surges, spikes and generator overloads.

5. Cooling and Exhaust Systems

Constant generator use causes working parts to heat up. A cooling system is a fixed part of any generator to regulate its temperature and prevent overheating. Most generators have either an air- or liquid-cooled system to regulate their internal heat.

Air-cooling generator systems rely on air circulation to bring the generator’s temperature down by drawing in air from the atmosphere and blowing it internally across the generator. One benefit of this type of cooling system is that it does not require a cooling water pump or any connection hoses. It also requires less maintenance because of the simplicity of an air-based system. However, air-cooled generators can overheat if used for a long period, which can cause them to fail or create irreparable damage.

Liquid-cooling systems use coolants or oil with a radiator and water pump to regulate a generator’s internal temperature. The pump uses a network of hoses to distribute the cooling liquid to the engine, where the liquid absorbs the heat and goes to the radiator to air-cool. These cooling systems cost more to operate and are more expensive. Also, they often require more attention and maintenance because they are more complex systems.

Additionally, because generators produce fumes containing dangerous chemicals, it is imperative to have a set framework to discard these fumes. Generator exhaust systems require a fume pipe that ends outside and leads away from entry points, doorways and heavily trafficked areas.

6. Lubrication System

Similar to any other machine with moving parts, generators rely on gears and levers, and these moving parts often generate friction. To ensure these parts can move with ease, generators require lubricant. Lubricant is a fluid or oil formulated to separate a generator’s internal components.

Regarding generators and their engines, lubricant has four primary purposes. The first is that it creates a film separation between the engine’s moving parts to prevent metal-to-metal contact. It also creates an oil film that forms a gas-tight seal between the piston rings and cylinder. Further, lubricant works to remove heat generated by the engine. Lastly, it helps keep the engine’s internal surface clean.

Generators rely on a lubrication system to eliminate friction between surfaces that come into contact under regular operating conditions. Manufacturers use a thin layer of lubricant on friction surfaces to reduce friction resistance.

It is important to avoid dry friction and friction resistance when possible, as friction can cause mechanical wear and reduced generator efficiency. A properly lubricated system allows the generator to do its job, and it improves and elongates the machine’s durability and reliability.

7. Battery

Batteries are a crucial part of a generator because they provide the power the machine needs to start during a power outage. When the power is out and you need a generator, there is no other energy source the machine can use except the battery. Specifically, the batteries power the engine starter and control panels. Some generators even have a secondary battery in case the primary one fails.

As battery failure is one of the top reasons for generator failure. Therefore, it’s important to conduct routine checks on batteries. An inspection requires you to clean and tighten any loose or dirty connections and ensure sulfates do not accumulate on the battery. It’s also important to know the shelf life of your generator’s battery. Its capacity will decrease over time and fall below 80% of its normal capacity. A general rule of thumb when it comes to batteries is that you should replace them every 4 years to ensure efficiency and operation.

8. Skid

The main frame or skid is the main base that a generator and its components are mounted to. In an indoor generator room, the skid is often mounted to the floor to ensure that it is held securely in place. This skid acts as a main base of a generator set and offers a lot of flexibility aside from holding generator parts and components.

Skid-mounted generators enable users to add an enclosure on top of the generator set that can either provide weatherproofing or even sound-attenuation with weatherproofing benefits for generators installed outdoors. For natural gas generators, the skid and enclosure are mounted on to a concrete pad. The concrete pad is measured and poured to support the weight of the generator and usually installed with stub ups, vibration isolator mounts, and cable connection cutouts in mind.

Diesel generators can also be mounted on top of a diesel base tank via the skid, which allows the diesel generator to have a fuel supply attached directly to the unit. For outdoor installations like this, diesel generators are also mounted to a concrete pad that not only supports the weight of the generator, but takes the weight of the diesel base tank into account as well.

Portable generators even utilize the skid. A majority of portable generators are diesel generators. This means that the generator set is mounted to a skid, the sound-attenuated enclosure is attached to the skid and the base tank is fixed below the skid. This entire package is then mounted to a trailer that enables users to move the generator from location to location as required.

Keeping generators up to code and functioning properly requires you to plan the frames before installation, as you’ll have many considerations to make. Specifically, you want to avoid mounting your generator somewhere with insufficient space for installation and maintenance. You also want to prevent generator pad overloading and legal or regulatory noncompliance issues, which can lead to fines or generator shutdowns.

9. Control Panel

The generator control panel is a collection of components displaying details and parameters, including current, voltage and frequency. Presented on either built-in displays, gauges or meters, control panels generally have switches or buttons to ensure the generator’s operation.

Newer control panels have programmable modules, while older ones rely on analog methods and manual adjusting. Control panels have a microprocessor that uses input from sensors to give feedback about the generator on the control panel. This setup allows the generator to monitor itself and manage any processes that may be irregular.

For example, one of the most common feedback settings is temperature. If the engine overheats, the sensors alert the control panel and adjust accordingly by finding a solution, such as shutting down the machine to prevent damage.

These control panels allow operators to see system functions, diagnostics and the generator’s current operator status. Because generators are heavy pieces of machinery, they are prone to overheating, wear and tear from constant use, speed fluctuations and engine fatigue. It is important to monitor your generator’s critical functions, such as oil and coolant temperature.

10. Enclosure

The major purposes of generator enclosures are to protect and quiet the machine. Before deciding on an enclosure for your generator, consider your priorities. Two types of generator enclosures you can choose between are weatherproof and sound-attenuated enclosures.

Weatherproof enclosures offer protection from moisture and extreme temperatures. However, these enclosures typically provide the bare minimum and do not have any special features that set them apart, except for possibly including greater protective methods for the weather.

Sound-attenuated enclosures are weatherproof and work to reduce noise produced by the generator. Generators can make a lot of noise, and the more powerful the machine is, the more noise it will create. This can be bothersome to those nearby, violate regulations and prove harmful to workers or those within the vicinity.

Find the Right Generator From Woodstock Power

At Woodstock Power, we take pride in providing our customers with quality and affordable electrical systems, ranging from generators to UPS systems to transformers. Offering only inspected, serviced and verified equipment, we ensure you can depend on our products.

We have industry experts with in-depth knowledge who will help you find the generators and products that best meet your needs and budget. Our commitment to providing reliable, cost-effective and high-quality machinery helps us serve the power generation needs of companies varying in size all across the United States.

To learn more about Woodstock Power, fill out our contact form or call us at 610-658-3242 with any questions or concerns.