Generator Cooling Systems: Air-Cooled vs. Liquid-Cooled Generators

For years, diesel generators have been a popular choice used within a wide range of industries and applications. Diesel generators are known to be sturdy and built to last over time, as well as handle heavy workloads when required. Because these units are powerful and fuel-efficient, they have been a staple in various industries, including airports, agriculture, amusement parks, off-site construction, mining operations, data centers, educational institutions and facilities, hospitals and healthcare facilities, and even commercial and industrial properties.

While diesel generators boast many benefits on their own, the cooling system is what enables these generator sets to truly shine. Whether you’re looking to buy a generator or currently own or manage a facility that uses generators, understanding the different generator cooling systems is key to enhancing your operation’s safety and efficiency.

About Air-Cooled Generators

Air-cooling systems are commonly used for standby and portable diesel generators and natural gas generators as a default option. This is due to the fact that they are more cost-effective when compared to liquid cooling systems or other similar advanced cooling systems. These generators use the surrounding air to help cool the engine by methods ranging from passive cooling to fans that blow air over the generator. These methods help prevent the generator from overheating. With their compact design and lower installation and maintenance costs, air-cooling systems are ideal for smaller commercial setups.

A great benefit of air-cooled systems is that the generator set does not require a radiator, water pump, temperature gauge or any connection hoses. You also won’t have to worry about the coolant freezing, boiling, leaking, evaporating or becoming contaminated or getting corrosion in the cooling system. Additionally, air-cooled diesel generators require less short-term maintenance, since the air-cooled system is relatively simple.

It’s important to keep in mind that air-cooled generators can overheat if used for a long duration of time. Overheating can cause the generator engine to seize, prompt the generator to shut down to prevent damage to the unit or irreparably damage the generator entirely. Air-cooled diesel generators are also fairly loud, as the fan generates noise as it blows air across the engine. It is also more difficult to reduce the noise levels via sound attenuation, due to the airflow required to keep the generator cool.

About Liquid-Cooled Generators

Liquid-cooled systems rely on a closed-loop cooling system and a coolant and fan system to remove heat. These systems are commonly used for standby and portable diesel generators with higher kW ratings, making them suitable for larger industrial applications. The pump helps to distribute cooling liquid to the engine block through a network of hoses. The heat produced from the engine block is transferred into the coolant, which then loops to the radiator, where it is then air–cooled.

Liquid-cooled diesel generators require more frequent maintenance when compared to their air-cooled counterparts, but it is often considered worthwhile for many diesel generator users. If using a diesel generator with a liquid-cooling system, you need to regularly check and monitor antifreeze levels, cooling liquid, hose connections and leaks.

One thing to keep in mind with liquid-cooling systems is that they have higher production costs, so they are often more expensive. The cost is usually worth the trade-off since liquid-cooling systems tend to be more powerful and durable when compared to their air-cooling counterparts. Overall, liquid-cooled diesel generators offer quieter operation, longer life span and better heat dissipation, which improves efficiency and performance under load.

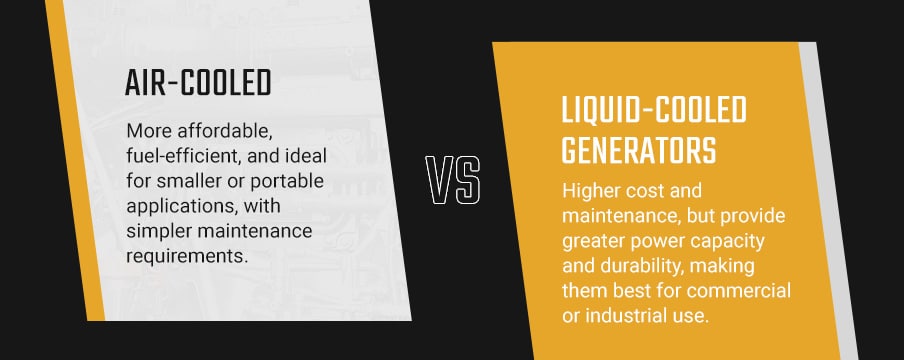

Air-Cooled vs. Liquid-Cooled Generators

If you are trying to decide between different types of generator cooling systems, it’s helpful to keep a few similarities and differences in mind. Consider features such as:

- Application suitability: Your specific application will play a significant role when deciding between these two types of generator cooling systems. Because liquid-cooled generators have heavy-duty components and can pull out heat faster, they are best suited for commercial or industrial use. Air cooling systems are preferred for generators that require less loads and less frequent usage.

- Cost: While several different factors can influence the cost, such as specific brands or models, liquid-cooled generators usually have a higher initial purchase price and installation costs. These systems are more complex and have heavier-duty components, which increases the cost. Because air-cooled generators rely on fans and a simpler design, they are typically available at a more affordable price.

- Power capacity: Power capacity is another factor to consider. Your generator size and use will impact the power capacity needs. Liquid-cooled generators use a radiator and coolant, which enhances their performance capabilities under continuous load. They are designed to be more durable and powerful to meet the needs of large businesses or operations. Meanwhile, air-cooled systems are more effective for smaller or portable generators because they don’t pull as much heat from the system.

- Efficiency: Since air-cooled generators are more portable and don’t use extra energy, they are more fuel-efficient. Liquid-cooling generators require more power to function, which may impact their overall efficiency.

- Maintenance: Maintenance requirements are another factor to consider. Both systems require regular maintenance to operate reliably. Air-cooled systems should be checked frequently to ensure dust and debris aren’t building up. The fans and cooling fins must be kept clean to run effectively and efficiently. The maintenance requirements for liquid-cooled systems are more complex, requiring specialized kits and more involved procedures.

The Woodstock Power Company Experience

If you are unsure whether a liquid-cooled or air-cooled generator is right for your industrial or commercial business, turn to Woodstock Power. Our industry experts have in-depth knowledge and focus on power generator sets.

We carry only the most top–rated new, used and surplus power generator sets and generator accessories for sale, providing you with a great value generator that will fit your budget. We also buy used generators in good condition. These generators have been thoroughly inspected, serviced and verified to ensure they meet industry standards.

From answering questions to helping you choose a power generator set, we’re ready to assist. We can help you pick the best generator for your needs based on:

- Stationary and portable power.

- Exhaust and space restrictions.

- Average and peak power requirements.

- Fuel preference — natural gas or diesel.

- Prime and standby generator requirements.

Our experts are also able to help coach you on Final Tier 4 regulations and the potential impact they can have on your generators. With benefits ranging from financing options to the capability to handle any size project, you can trust that our time will do what it takes to help you find the perfect generator solution.

Reach out with any questions or inquiries to learn more about our generator solutions.