How to Manage a Commercial Grow Operation

The cannabis industry is booming. In Colorado, where marijuana is legal for both recreational and medical use, sales of marijuana were over $1.7 billion in 2019. Illinois, which legalized recreational use of marijuana at the start of 2020, saw sales of more than $39 million during the first month of legalization. In Pennsylvania, where medical marijuana is legal, sales topped half a billion dollars during the first two years of legalization. Thanks to the potential for a large profit, the idea of starting a commercial grow room is appealing to many. But managing a grow operation involves more than just planting a few varieties of marijuana and hoping for the best.

Although marijuana is hardy and easy to grow, it does need some care and attention from people to produce the best results and yield a successful harvest. Just like any other business, managing a commercial grow room requires some business sense and know-how. It also requires some knowledge of the conditions the plants need to thrive and the type of care and attention they need throughout their life cycle. If you are setting up a grow room for the first time or want to improve your marijuana operations, here’s what you need to know to manage indoor grow operations successfully and to get your foot in the door of the cannabis industry.

How to Get Started With a Grow Op

Starting a grow op involves more than placing some plants in a room, turning on bright lights and hoping for the best. There are legal considerations as well as practical considerations to keep in mind as you get started. For example, in Pennsylvania, you need to apply for a permit to grow marijuana and the number of permits available to growers and processors is limited. There are also fees involved in the application process, including a $10,000 non-refundable initial fee and a $200,000 refundable permit fee. If you’re awarded a permit in Pennsylvania, you’ll need to complete a two-hour training course.

It’s a good idea to consult an attorney before you apply for a grower’s permit as well as while you set up your grow room to ensure you follow the code or law of the state where your grow operation is located.

Setting Up a Grow Room

In Pennsylvania, marijuana growing operations need to be located indoors. There are other requirements for the facility, including a rule that certain areas need to be marked with clear signage. You’ll need signs that label the growing areas of the facility, the office areas, areas with restricted access and reception areas. Additionally, the facility needs to have a secure, enclosed area for accepting deliveries of seeds, immature marijuana plants and other marijuana plants or products.

Another essential part of setting up a grow room is establishing a security system. In Pennsylvania, for instance, the legal code requires grow houses to have a professionally-monitored security alarm. The security system needs to include both audible and silent alarms and provide coverage of the entrances and exits of the facility, as well as the windows, exterior walls, skylights and storage areas. A surveillance system is also a must-have in a grow house in Pennsylvania.

Once you’ve addressed security concerns, you can focus on commercial grow room equipment. Like any other plant, marijuana needs light, humidity and fertilizer to thrive. Temperatures in the grow room should also be relatively stable. Since the cost of caring for the plants can climb, it can be helpful to implement cost-saving measures into the grow operation. For example, you might install solar panels on the roof of the grow house to help supply electricity. Having a back-up generator is also imperative, in case there is a loss of power. It’s also a good idea to install rain barrels or another way to collect rainwater and use it to humidify the grow room or for irrigation.

Another part of setting up your grow room is hiring the right people. Employees should be over the age of 18 and trained so they are well-versed in the rules of your state and understand the importance of following the law.

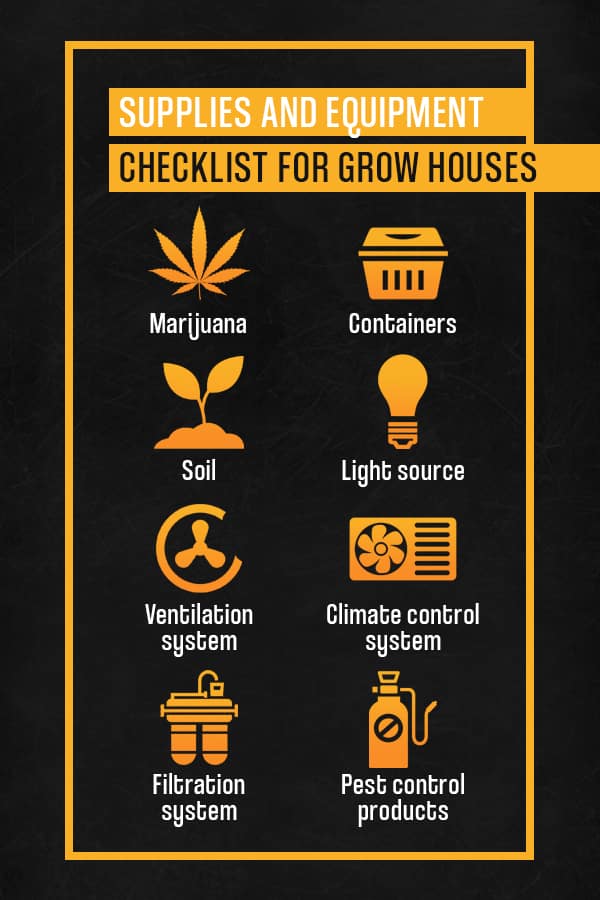

Supplies and Equipment Checklist for Grow Houses

Part of successfully managing a grow room is having the appropriate supplies and equipment for the facility. Here’s what you’ll need for your operation:

- Marijuana: Whether you decide to grow your plants from seeds or use clones is up to you, but you can’t have a grow operation without something to grow.

- Containers: A wide variety of containers are available for growing marijuana. You’ll most likely need one container for each plant you decide to grow. The containers should be large enough to support mature marijuana plants — usually about 5 gallons. They should also have drainage to keep the soil and roots from becoming water-logged.

- Soil: If you’re going to grow your plants in soil, you’ll need an appropriate type of potting mix to provide the correct amount of nutrients and to help manage moisture levels.

- Light source: Marijuana needs light to thrive, so you’ll need some type of grow light system. LED grow lights are usually more energy-efficient than other options, helping your business save on energy costs.

- Ventilation system: The plants will need good airflow to thrive. Stagnant air encourages the growth of mold and fungus and prevents the plants from getting the carbon dioxide they need. The ventilation system should expel air from the room through the windows or ducts and take in fresh air from outdoors.

- Climate control system: Marijuana plants need the air to be a particular temperature for the best results. A climate control system allows you to raise or lower the temperature in the room. You might also consider a climate control system that lets you adjust the humidity in the grow room as needed.

- Filtration system: Indoor grow operations can be very fragrant. To help improve the odor in the room, install a filtration system.

- Pest control products: To protect the plants from pests, insecticides and other pesticides might be needed. You might also use a system such as integrated pest management (IPM) which only uses chemical products as a last resort.

Monthly Grow Room Calendar

Like other plants, marijuana grows in a consistent pattern. The plants start as seeds or cuttings, spend several weeks developing a healthy root system, several weeks producing leaves and the final weeks of their lives producing flowers. The typical plant has a three-month growth cycle. To make sure everything runs smoothly in your operation, you might want to create a monthly grow room calendar. The calendar will let you and your employees know when to feed the plants, how much water to give them and if it’s time to adjust the lights.

Month 1

During the first week of the first month of a grow cycle, it’s time to plant the seeds or to root cuttings taken from a mother plant. You’ll want to plant the seeds or cuttings in small pots filled with container soil or a seed-starting mix. Placing the pots under a dome or glass enclosure will help to ensure they get the humidity they need during the first phase of life.

After two or three weeks, the baby plants will be ready to move to larger containers. Carefully plant the seedlings in the bigger pots. At this point, they also need light. Position grow lights a couple of feet above the plants. Now’s the time to begin fertilizing the plants, using a diluted solution. You’ll also want to make sure they receive adequate amounts of water. The soil should be damp but not soaking wet.

Month 2

By the beginning of the second month, your baby plants will be much stronger and tougher than before. They’ll be able to handle more fertilizer and light. You can move the light source closer to the plants at this point. The grow lights can be as close as one foot away from the plants. You can also begin to use a full-strength fertilizer, rather than diluting it to half the recommended strength.

Now’s the time to keep a close eye on your plants so you can spot and treat any issues quickly. Look out for yellowing leaves, which can mean the plant isn’t getting the nutrients it needs. If your plants are showing signs of stress, you might need to play detective to figure out what’s going on. Pests, limited light, too much water, not enough water and too much or not enough fertilizer are all things that can stress your plants.

Month 3

At the start of the third month, you should be able to tell which plants are male and which are female. If you planted clones, all of the plants should be female, but if you grew from seed, you might get a mix of male and female plants. If you want to produce seed for the next round, you can keep the male plants in the room. Otherwise, you’ll want to remove them. Now’s also a good time to take cuttings from the female plants for clones.

Month three is very critical, as it’s when the plants begin to produce flowers. They’re going to use up a lot of energy and might need more fertilizer, water and light. Keep an eye on the plants for any signs of stress. You might need to increase ventilation in the room, adjust the temperature or increase the light. The more light in the grow room, the more likely your plants will be to produce buds.

Also, keep a close eye on water levels during the third month. If the soil dries out, your plants will be stressed, which can cause them to lose leaves or flowers. If you see any signs of dried up leaves or damage to the leaves, prune them away to improve the health of the plants.

Month 4

The buds or flowers on the plants will get bigger and heavier at the beginning of the fourth month. The plants are ready to harvest at this point. Additionally, any cuttings you took from the plants should be rooted and ready to start the growing process once again.

Daily Grow Room Checklist

Along with having a month-by-month plan for your grow room, it’s important to have a daily checklist that employees can follow to ensure that the plants are healthy and all systems are in order and operational. Your daily checklist might look something like this:

- Inspect the plants: Someone should look at each plant in the room daily to make sure they all are getting the water they need and the appropriate amount of fertilizer. Look for signs of nutrient deficiencies, inadequate water or humidity or general signs of stress. Everyone working in the grow room should know how to diagnose and treat plant problems.

- Check and adjust lights: It’s also important to check the lights daily. Look for burnt-out bulbs and replace them as needed. Also, make sure the lights are the appropriate distance from the plants. Raise or lower them as needed.

- Check ventilation system: The ventilation system needs to be in good working order to keep the plants happy and reduce the chance of them becoming moldy or otherwise stressed. Inspect the system daily to make sure the fans are blowing at the appropriate speed and the air is moving through the room as it’s supposed to.

- Check temperature and moisture levels: The temperature and humidity level in the grow room might need to change as the plants mature. Each day, check that the temperature is set to the right level and the humidity is within range.

- Look for pests: It’s also a good idea to check the plants for signs of pest damage, such as chewed leaves or damage to the stems. Check the room daily to ensure pests have not built any nests or otherwise been able to get in.

Power Needs for Grow Rooms

The lights, ventilation system, heating and cooling systems and irrigation systems in your grow operation all need a source of power to continue to operate. Generally speaking, a grow room can use around 5,000 kilowatt-hours per year for every four plants in the room. Successfully growing marijuana indoors requires ample amounts of electricity, and the source of that electricity must also be continuous. If there’s a power outage, the plants can experience significant damage. For example, loss of power can result in the lights going out, which can prompt the cannabis plants to premature flower early, resulting in a lower yield and a negative impact to your bottom-line.

To ensure continuous power, it’s a smart idea to have a back-up power supply for your grow room, in case of a power outage or other issue with the electrical supply to your facility. Along with having a back-up source of power, it’s also essential for the back-up is sized appropriately for your facility. A back-up generator that is too small will not be able to deliver the power your room needs to keep the lights on, the fans going and the heating or cooling system functional.

Before choosing a source of back-up power for your grow operation, it’s important to know how much electricity your grow houses use. Your generator won’t need to supply the full amount of power the facility uses but should provide enough to keep the lights on and other essential equipment running.

Another thing to consider when choosing a back-up source of power is the fuel the generator uses. Fuel options include diesel and natural gas, and there are pros and cons to each option. Woodstock Power offers both types of back-up generators, and we’re happy to work with you to help you choose the equipment that will best meet your needs.

Indoor Grow Operations Depend on Consistent Power

As you work on getting started in the cannabis industry and on setting up your grow room, don’t forget the importance of a regular power supply. Managing your grow operations means having the power needed to supply the plants with light, water, humidity and airflow.

Woodstock Power will work with you to help you choose the best back-up generator for your operation. Browse the generators we have for sale, then get in touch with us today with any questions you have. We’re happy to guide you through the process of choosing the right generator for your needs.