What is Generator Synchronization?

Generators are your dependable backup power source, but they still need some support from time to time. When a generator reconnects to a power system after an outage, maintenance, or load adjustment, synchronization is essential. Synchronization helps match the generator parameters with the grid or other generators to keep everything stable. Without this process, you risk power surges and performance issues. Understanding generator synchronization is a valuable step in protecting your facility and ensuring the reliability of your emergency power systems.

Understanding Generator Synchronization

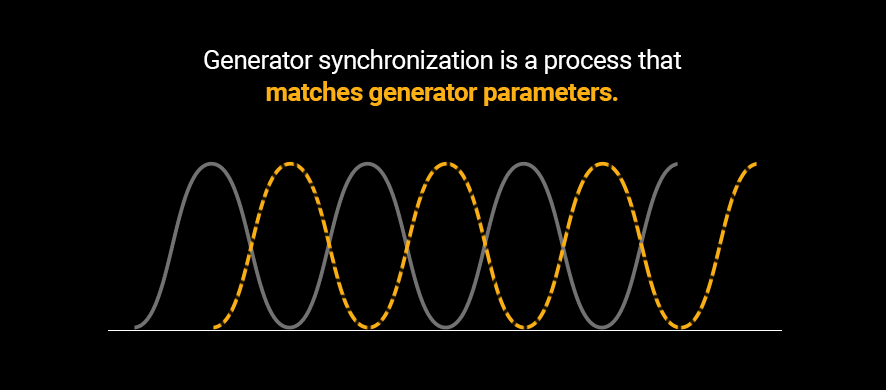

Generator synchronization is a process that matches generator parameters such as voltage, frequency, phase angle, phase sequence, and waveform. Once these parameters match, you can connect the generator to a power source.

In the majority of cases, automatic synchronization of generators is the standard. The process is automated via an automatic synchronizer with manual control capabilities that can be used in backup situations. If done correctly, synchronization lets generators share loads efficiently and deliver stable power across your systems.

Automatic Vs. Manual Synchronization of Generators

Technicians can perform generator synchronization manually or automatically, depending on the system and application. Here’s how each process works:

- Automatic: Automatic synchronization uses a sync-check relay or automatic synchronizer to constantly measure generator parameters. Once it detects parameter alignment, it closes the breaker. This reduces human error and makes synchronization more precise.

- Manual: Manual synchronization of generators requires an operator to monitor and match parameters. They use indicator lamps and synchroscopes to carefully time the process. Any errors can lead to safety hazards or the malfunction of the generator.

Why Is Generator Synchronization Needed?

A generator cannot deliver power to an electrical power system unless the parameters match those of the network. If you have two or more alternators supplying power, they need to be synchronized. Since electrical loads do not remain constant, the two or more generators supplying the power need to be interconnected and operate in parallel to handle larger loads.

Using a series of small units instead of a single generator is known as parallel operation. Synchronization of generators in parallel offers your facility:

- Reliability: With multiple alternators, parallel operation is much more reliable than single-unit generators. In a single-unit system, the whole setup will shut down if the alternator fails. In parallel systems, one alternator can fail and the other units will keep the system active.

- Continuity: If a unit needs maintenance, the other systems can stay up and running to prevent your entire operation from stopping.

- Load: Your load requirements may vary throughout the day. Adjust your parallel system to accommodate higher and lower loads with more or fewer active systems.

- Efficiency: Generators run at the highest efficiency when they operate at their load rating. By adapting to load changes, your system can remain efficient at all times.

- Capacity: Bigger operations require more power. With more generators, systems have more alternators for increased capacity.

Generator Synchronization Techniques

While automatic processes handle everything for you, manual synchronization needs a careful strategy. There are three main techniques for manually synchronizing generators. Each uses specific visual signs to make the process successful.

Three Dark Lamps Method

This method uses a bus bar to synchronize the second generator. Three lamps are placed between the generator and the bus bar. Then, they’re connected to the corresponding phases. When all the lamps go dark, it means the generator is synced properly. It’s an easy-to-understand method, but it provides no information on frequency.

Two Bright, One Dark Method

This method also involves connecting lamps to a bus bar. The order of lamps that light up or stay dark provides information about the generator frequency. If the first two lamps are bright, the alternator is running slower. If the middle lamp stays dark, the alternator is faster. While this method is slightly more accurate than three dark lamps, it lacks phase sequence information.

Synchroscope Method

This method is the most accurate. The synchroscope offers information on both the phase and frequency. Operators can watch the synchroscope needle as it swings. Once the pointer is centered, the operator knows the generator is synced.

Requirements for Synchronization of Generators

Generators must be aligned for safe, successful connection. Each parameter affects safety and performance, so make sure you understand each of these and how to match them:

- Phase sequence: Your system’s alternators should have the same phase sequence as your electric grid or bus bar.

- Voltage magnitude: The generator’s voltage must also match the bus bar. When the alternator voltage is higher than the bus bar, you’ll create a high reactive power in your grid that could pose safety concerns. If the alternator voltage is lower, the generator will absorb high reactive power from the bus bar and potentially fail.

- Frequency: When frequencies are unequal, they create an unstable flow of energy. This instability may lead to damaged equipment.

- Phase angle: The phase angle of the bus bar and generator alternator must be zero.

Your generator synchronization procedure will help you determine if these parameters are equal between your bus bar and generator alternators.

The Consequences of Faulty Generator Synchronization

If there are issues with generator synchronization, you risk:

- Generator and prime mover damage due to mechanical stress caused by rapid acceleration or deceleration.

- Damage to the generator and step-up transformer windows due to the high currents.

- Disturbance to the power system, such as oscillations and deviating voltages that are not nominal.

- Generator shut-off due to abnormal operating conditions.

- Destruction of the generator due to faulty voltage.

With all the possible risks of faulty synchronization, it’s critical for all operations to take the appropriate measures during the process. Consult a professional if you’re unsure about the steps to take, and they’ll help you keep your system up and running.

Contact Woodstock Power for More

At Woodstock Power Company, we specialize in generators and the things they need for synchronization. If you would like more information about generator synchronization, the process or techniques to do it, our staff at Woodstock Power would be happy to help. Our team offers generator support so you can keep your facility running.

We are industry leaders in buying and selling used generators to fit the needs of many businesses, including commercial, industrial, medical, agricultural, and university. This includes facilities like hospitals, better living centers, nursing home, airports, hotels, resorts, restaurants, retail centers, manufacturing, production, and more.

Our experts are ready to assist you, from answering any questions you may have about power generator sets to helping you find the best selection in our inventory based on:

- Peak & Average Power Requirements

- Fuel Preference (Natural Gas or Diesel)

- Portability & Stationary Power

- Prime & Standby Generator Requirements

- Available Space & Exhaust Restrictions

We carry only top-rated new, used, and surplus power generator sets for sale, providing you with a great value generator that will fit your budget. Based in Philadelphia, we provide reliable commercial generator solutions nationwide.

Our generators have been thoroughly inspected, serviced, and verified, which ensures that you will be buying a quality generator that you can depend on. If a generator is not up to par with industry standards, we make all necessary repairs or modifications and fully test every generator before we sell. This ensures a full turnkey generator that’s ready to fire up and go!

Due to our wide selection of generator sets, we’re confident that we can find the model that best suits your operational needs and budget.

We also buy used generators in good condition, if you have already upgraded and you’re looking to sell your older model.

Feel free to contact us with any questions, concerns, or inquiries to learn more about the Woodstock Power Company experience and the quality level of products & services we provide.